What are the benefits of green manufacturing and the changes we can accomplish

Green manufacturing

Green manufacturing refers to manufacturing practices that do not harm the environment during the production process. It addresses various supply chain issues such as recycling, conservation, waste management, water supply, and several others. These objectives are frequently met through product and process design.

Green manufacturing means reducing pollution and waste by minimizing natural resource use, recycling, reusing waste, and reducing emissions. It establishes renewable production processes and environmentally-friendly practices in manufacturing businesses. These techniques help limit a manufacturer’s impact on the ecology.

The energy-intensive plastic production

If we backward integrate the entire supply chain, plastics are a pivotal element of the oil and gas network. From the crude oil, various hydrocarbons are produced. These are further cracked in Naphtha or Gas crackers to produce ethylene or propylene gases, which are the base raw material for plastic. These gases are reformed in polymer plants to make LDPE, HDPE, polypropylene, and other polymer pellets. These pellets are then used to make several types of plastics. They are delivered to factories, where they are melted and moulded into various plastic items like water bottles, food packaging, auto parts, medical devices, and several other products. Despite its utility, the fact is that manufacturing plastics requires a significant amount of labour, expertise and energy. Businesses should keep pace with technical developments and adapt accordingly. Instead of a tubular reactor for LDPE, which operates at very high pressure, autoclave reactor technology, which runs at lower pressure ranges, can be used.

In addition, utilities such as compressed air, chilled water, plant air, among others, are critical in any manufacturing plants and must be effectively managed and optimized to reduce energy costs. Energy efficiency is not just about upgrading hardware; production staff can be trained to optimize the plant’s energy index. Green buildings with a LEED(Leadership in Energy and Environmental Design) rating can be used to construct plant control rooms, reducing energy consumption significantly.

Benefits of green manufacturing

- Use of renewable energy – Manufacturing often necessitates substantial amounts of energy. Businesses should switch to renewable energy sources, putting less strain on the energy supply and lowering their environmental impact.

- Increase energy efficiency – Businesses can not only change their energy source, but they can also improve the amount of power required to manufacture products by investing in improved technologies.

- Pollution reduction – Reducing the amount of pollution produced by a business impacts the environment. This can be accomplished by recycling and using innovative technology to reduce harmful emissions.

- Conserve natural resources –When large manufacturing plants wreak havoc on the environment, manufacturers should give back by pledging to safeguard ecosystems.

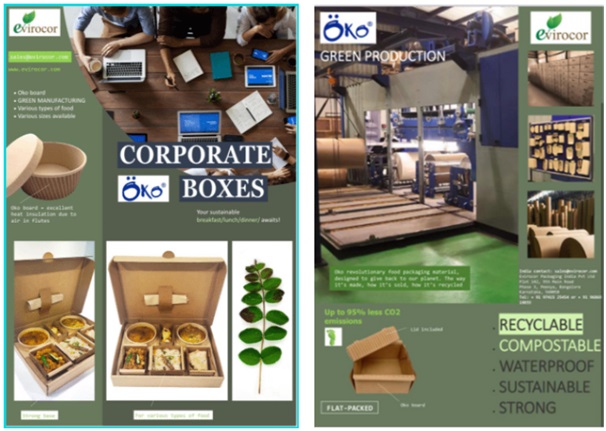

Evirocor’s efforts in green manufacturing

Evirocor is unwavering in its commitment to the environment, sustainable practices and makes an exceptional effort to practice green manufacturing. However, going green can have significant upfront costs. Evirocor was able to get started thanks to various incentives. Their patented Cortec-Revolution system reduces CO2 emissions significantly and is based on a sustainable raw material supply. When Evirocor decided to become a green manufacturer, they actively promoted values in which they firmly believed.

Conclusion

Going green is evidently beneficial to the environment, and it is something that many manufacturers strive for, but eventually, it should also benefit the bottom line. Technology has dramatically improved green manufacturing processes, and the public’s purchasing preferences are increasingly influenced by sustainability and environment conservation. Effective leaders recognize that governments are interested in promoting brands to go green, and it is possible to make changes while improving profitability. Going green is not something that can be accomplished overnight, but it is something that can be started now.