How to Decrease Carbon Footprint Using Sustainable Packaging Products

What are green food packaging products?

Green food packaging products, which are also known as sustainable packaging products, use materials, sourcing and manufacturing techniques to cut energy use and limit the baleful impact on our environment. Green packaging solutions usually consist of biodegradable and re-processable materials. This is in preference to single-use plastics. Green manufacturing processes ensure the reduction of their power requirements and diminish the number of greenhouse gases (GHGs) they produce.

What are greenhouse gases (GHGs)?

Greenhouse gases are present in the Earth’s atmosphere and absorb heat. The more these gases remain in our environment, the more heat will be retained in our atmosphere.

The major GHGs present in the environment are:

- CO2 – Carbon dioxide

- CH4 – Methane

- N2O – Nitrous oxide

- SF6 – Sulphur hexafluoride

- CFCs – Chlorofluorocarbon

Carbon dioxide is the primary GHG emitted due to uncontrolled activity. Also, with the rampant cutting of green cover, less CO2 is being absorbed by plants leading to the accumulation of CO2 in the Earth’s atmosphere leading to rising temperatures.

What is a carbon footprint?

GHGs are required in appropriate quantities to maintain the Earth’s temperature. Without them, Earth would have been a colder planet, unfit for human habitation.

A carbon footprint is a modern term to describe the quantity of GHGs added to the atmosphere due to some human activity, as measured in the equivalent amount of carbon dioxide released.

Why is plastic production an energy-intensive process?

Let us back integrate the entire process of plastic production. For example, one of the polymers for single-use plastic is low-density Polyethylene (LDPE), which is manufactured using Ethylene as feed-stock, coming from Naphtha or gas cracker plant. This Naphtha or hydrocarbon gas mixture comes from the distillation of crude oil in the refinery. This crude reaches the refinery through ships from the wellheads.

This is a very energy inefficient process. Some leaks can occur at the wellheads. Usually, there are leaks from the pipelines that bring oil and gas to a refinery. Besides, the process of converting oil or gas into polymer and plastic is energy intensive. In a nutshell, plastic is among the most energy intensive materials to produce.

How do green food packaging products decrease carbon footprint?

Green packaging products address the carping issue of plastic waste piling up on land and in landfills, as well as it will lead to lesser manufacturing of plastic, thereby saving crude oil and other material resources.

Bangalore – a city with a ravenous appetite for growth

Bangalore is a flourishing city with hundreds of innovative start-ups mushrooming daily. The city has 1/3rd of its population in the age bracket of 15-35 years. It also has India’s most internet-savvy consumers with a digital spend of around ₹8600 per person per month. Hence, Bangalore is one of the fastest-growing cities in India. A lot of youngsters stay without family in the city, with such a high disposable income. A lot of them spend their money on packaged food, which comes from nearby local joints. Meals are usually packed and dispatched to the offices and homes for these busy youngsters.

Evirocor’s efforts – a modest beginning towards a big goal

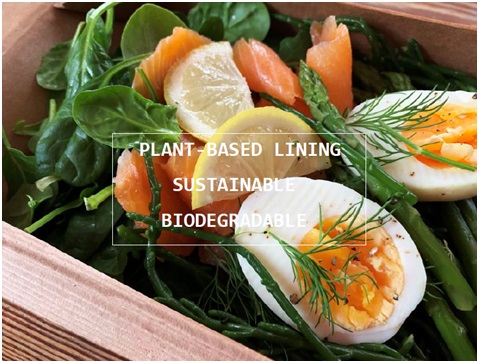

Evirocor’s Oko sustainable packaging products based in Bangalore have a huge future potential, because they reduce the CO2 emissions in their production of Oko food packaging and Oko E-packaging made on Cortec-Revolution system. Oko products are made from earth-friendly, plant-based, home compostable and natural raw materials to leave a lesser carbon footprint and to eliminate the need to recycle or landfill single-use plastic packaging, thus reducing CO2 emissions considerably.

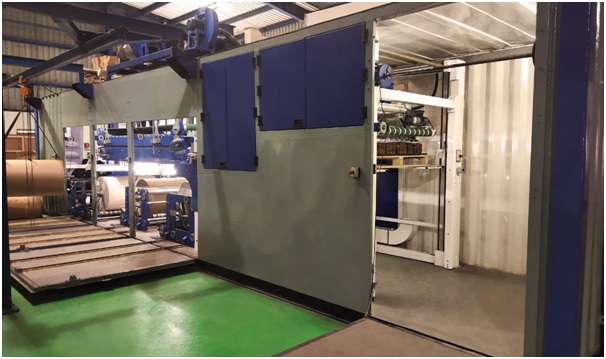

Evirocor’s Cortec-Revolution system

Evirocor’s Cortec-Revolution is an environmentally friendly paper corrugating system which produces Oko earth-friendly food packaging & Oko E-packaging. Since it requires NO HEAT INPUT in production, it reduces CO2 up to 95 %. If all corrugated board is made the Evirocor way, CO2 emissions would be considerably reduced by millions of tons annually.

How about you?

You too can contribute a lot just by sharing this article with your friends and over social media. Join this fight against plastic waste by being a change initiator, an influencer, an awareness champion… your single click to share, can make a significant difference.